The alumina short fiber is mainly composed of alumina and silica, and adopts the internationally leading "sol gel" preparation process. Its performance indicators are at the international leading level, and it has excellent flexibility and fire resistance and thermal insulation performance.

The service temperature of α-Al₂O₃ Fibre is up to 1400℃-1800℃; After treatment with liquid nitrogen (- 196℃) for 24 hours, the strength did not decrease.

Retention of fiber strength after 24h immersion in 10% alkaline solution: NaOH--40%; KOH--65%; NH₄OH--95%; Retention of fiber strength after 24h immersion in 10% acid solution: HCl--96%; H₂SO₄--95%; HNO₃--96%; H₃PO₄--95%.

Our fibers are free of slag balls (≥45μm), which makes the strength of the fibers improved to a certain extent, and at the same time, since the thermal insulation and refractoriness of the fibers are inversely proportional to the content of slag balls, the lower the content of slag balls, the higher the thermal insulation and refractoriness performance.

The resistance of alumina fiber decreases with the increase of temperature, and above 600℃, the resistance tends to be constant; the dielectric constant and dielectric loss of alumina fiber are basically stable at high temperature, which is suitable for making high-temperature wave-transparent materials.

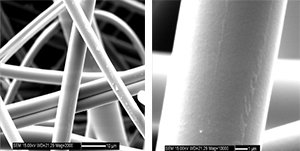

The fibers are highly flexible and do not break easily during the needling process.

By regulating the chemical composition and heat treatment process, products with different properties can be obtained to meet different application requirements.

| Product Type | Type 72-F | Type 72-M | Type 85 | Type 95-M | Type 95-N | |

|---|---|---|---|---|---|---|

| Chemical CompositionAI₂O₃:SiO₂(%) | 72-75:25-28 | 72-75:25-28 | 85-88:12-15 | >95:<5 | >95:<5 | |

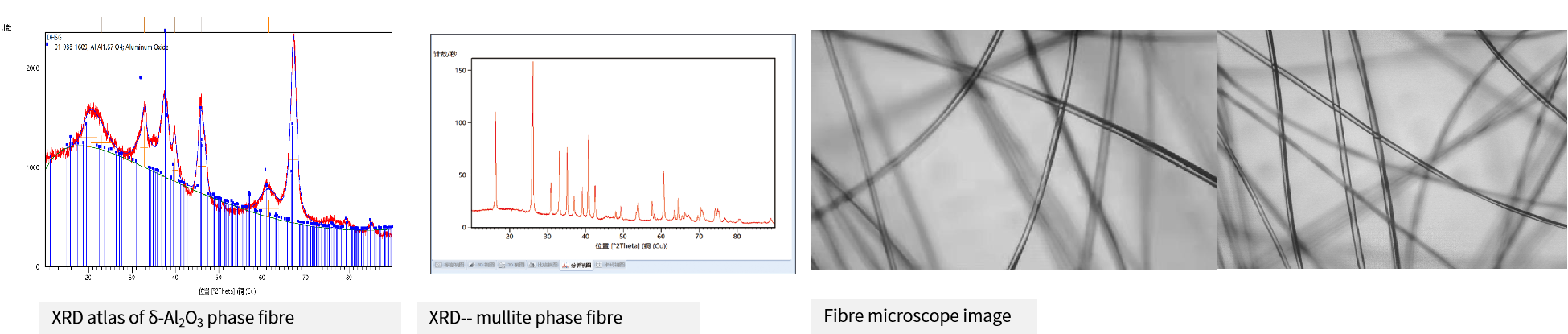

| Mineral Structure |

δ-AI₂O₃ or γ-AI₂O₃ | Mullite | Mullite+α-AI₂O₃ | γ-AI₂O₃ | α-AI₂O₃ | |

| Classification Temperature(℃) | 1600 | 1600 | 1800 | 1600 | 1800 | |

| Molten Point (℃) | >1800 | >1800 | >1800 | >2000 | >2000 | |

| Density (g/cm³) | 3.1 | 3.1 | 3.2 | 2.8 | 3.4 | |

| Average Fibre Diameter(μm) | 5.5-7.5 | 5.5-7.5 | 4-7 | 3-4 | 3-4 | |

| Shot Content (%) | ≥45μm | 0-2 | 0-2 | 0-2 | 0-2 | 0-2 |

| Impurity(%) |

<0.5 | <0.5 | <0.5 | <0.5 | <0.5 | |

| Monofilament tensile strength (MPa) |

≥1200 | ≥1000 | — | — | — | |

| Monofilament tensile modulus(GPa) | ≥100 | ≥100 |

— | — | — | |

Chemical composition of type 72 polycrystalline alumina fibre: the content of Al₂O₃ is 72%-75%, the content of SiO₂ is 25%-28%, and the content of other impurities such as Fe and Na is less than 0.5%. Under the microscope, it can be visually observed that the fibre diameter is uniform without slag balls, and the fibre diameter can be stably controlled at 5.5-7.5 μ m. Monofilament strength ≥ 1000MPa, and all indexes can reach the international advanced level.

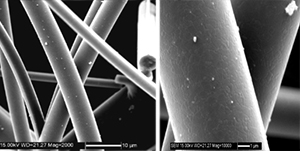

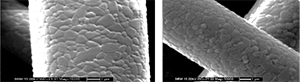

Microstructure: under the scanning electron microscope, the surface of polycrystalline alumina fibre is smooth and dense without holes and cracks. It indicates that the internal bonding of the fibre is dense, and there is no obvious grain boundary.

|

|

|

| SEM of DH fibre after heat treatment at 1200 ° C | SEM of DH fibre after heat treatment at 1400 ° C | SEM of DH fibre after heat treatment at 1600 ° C |

*REQUIRED FIELDS